|

|

.gif) |

|

|

|||||||

| Self Bonding Wire |

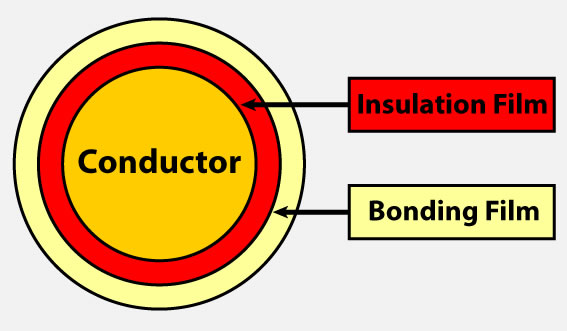

Magnet wires are made by spread insulating or multilayer in each kind of conductor line material after dryings. Self-bonding Wire is a kind of special magnet wire where the conductor is enamelled with two layers. The inter layer is insulation film and outer layer is a self-bonding film. The characteristics and usage are based on the conductor, coating and varnish film thickness. The main uses are on the speaker coils, buzzer coils, micro vibrant motor coils, actuator coils of HDD, pick up coils, antenna coils, sensor coils and the other electronic products etc.

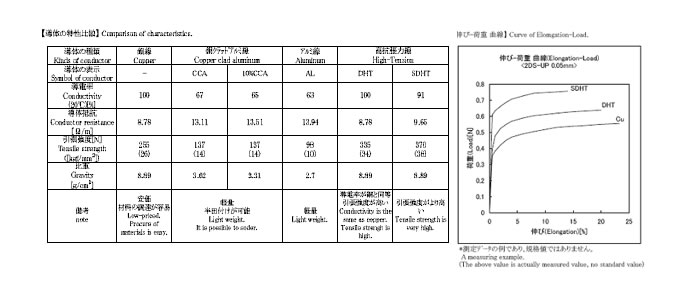

The following are some general information on material selection to determine the appropriate design in your product:

*1 Temperature Index is defined by thermal endurance test based on JIS C 3003 20., it shows guarantee temperature for 20,000 hours.

*2 Symbols mentioned in table are identification of DAIKOKU original.

*3 These characteristics are only for our lab purpose and are not guaranteed.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Please contact our nearest office for detailed enquiry of this product. |

|

||

© Copyright 2013 NYP Trinity Limited. All rights reserved |

||