|

|

.gif) |

|

|

|||||||

| Back to New Products | |||

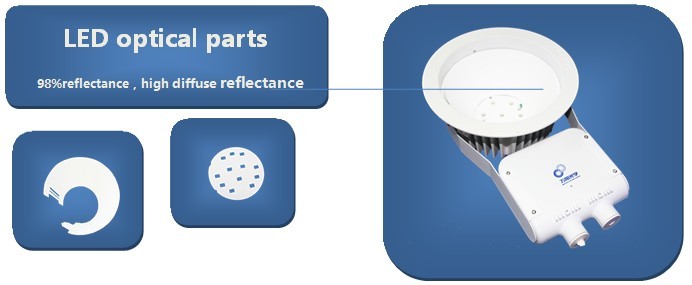

| 一、Essential for LED lighting | |||

|

|||

二、WhiteOptics Asia Pacific |

|||

|

|||

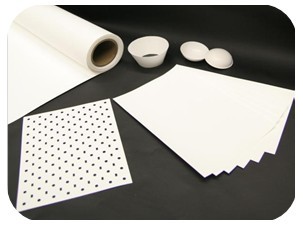

White97 Film F23 White97 Film F23A (with adhesive backing)

|

|||

High Diffuse Reflectance across visible spectrum,Up to 98% Reflectance |

|||

Raw Material Supply in Roll / Sheet form Release Liner can be supplied |

|||

in ring form by punching or cone shape by thermoforming.

|

|||

Whiteoptics reflective film is polymer composite with high reflectance across visible spectrum which can be applied |

|||

to lighting fixtures to improve lighting in the brightness and efficiency. It has a unique matte appearance, with strong |

|||

diffuse reflectance. By using Whiteoptics reflector, glare lighting is greatly reduced and "ribs spot effect" also successfully |

|||

minimized. The reflective material in the whole visible spectral range up to 98% reflectivity, and reflectivity of the uniform angle

|

|||

Whiteoptic Film mainly used as the reflector of lighting fixture included traditional CCFL and LED light sources products. |

|||

Both light efficiency and luminance can be improved with White97 Film family. |

|||

Whiteoptics Film is developed and manufactured specially for the lighting industry not only the traditional lighting fixture |

|||

but also take a important role in LED lighting. Due to the high flexibility of material characteristics, White97 can be |

|||

easily handled in the forming stage such as punching, bending and even thermo-forming. With the high diffuse reflectance, |

|||

high efficiency lighting design can be achieve without any difficulties for LED lighting.

|

|||

|

|||

UV stability |

Does not yellow with exposure to ultraviolet |

||

1000 hours UVA (340nm), less than 0.5% reflectance change |

|||

1000 hours UVB (313nm), less than 0.5% reflectance change |

|||

Thermal Stability |

2000 hours @ 80°C, less than 0.5% reflectance change | ||

Humidity Stability |

1000 hours @ 60°C, 95%RH, less than 0.5% reflectance change | ||

Abrasion Resistance |

Taber abrasion test switch 500, rate of change of reflectivity is less than 0.5% |

||

| Chemical Resistance | Compatible with most common cleaning solutions including ammonia, 409, dilute bleach solution | ||

and alcohols |

|||

|

||

© Copyright 2013 NYP Trinity Limited. All rights reserved |

||